Product overview

XMDA-6000 series intelligent itinerant display and alarm instrument is no longer a simple itinerant instrument in the past. Most of the products of this series of instruments have strong processing capacity of calculation, comparison, execution, alarm, etc. Xmda-6000 series intelligent itinerant display and alarm instrument adopts a special integrated circuit developed by ourselves and commissioned by Japanese integrated circuit manufacturers. It not only integrates most functions of various kinds of regulating instruments in the day ahead automatic control system, but also integrates circuits such as CPU, I / O interface, EPROM and D / a conversion, supplemented by software that is widely used, carefully prepared and repeatedly debugged The system makes this instrument unique in the following aspects:

1. The instrument hardware is greatly reduced, and the system structure is relatively simple. A variety of input signals are compatible within the scope of user application.

2. The optimized design is adopted, the process is significantly improved, there is no flying wire, no potentiometer adjustment, all the calibration and function setting can be completed by the software through the keyboard.

3. It can be set as four point control plus ten point patrol function. It can be set as unified point alarm or independent separation alarm function.

4. Up to four alarm outputs can be set, and more than ten alarm methods can be used, and sound and light monitoring can be carried out for each alarm point, and the sound of the alarm can be set, and the silencing delay time can be set.

5. The anti-interference modes of nearly one hundred levels in four categories set by the user can adapt to the interference sources of various environments.

Therefore, this instrument has a considerable improvement and breakthrough in various functional levels compared with the ordinary patrol inspection, and its reliability and stability are guaranteed. At the same time, this instrument is not only in line with the current international similar instruments, with a higher performance price ratio, more suitable for the national conditions, which is of great significance to replace imports.

Working principle

XMDA-6000 intelligent patrol alarm instrument is composed of patrol measurement circuit, digital panel meter, regulator and power supply. The regulated power supply converts the 220V mains power into the stable DC voltage as the other part of the power supply. The itinerant measuring circuit is to select one of the circuits to be tested and send it to a / D conversion and then to jc-588 special central processor for processing. After processing, it is not only to be sent to the digital panel meter, but also to the regulator. After comparing with the set value, it outputs the control or alarm signal according to the regulation law.

Product selection

| XMDA |

—— |

Instruction

|

|

Design No.

|

6 |

6000 series instrument

|

|

Display model

|

1 |

Measure 10- way inspection

|

| 2 |

Measure 10- way inspection , 10 alarm (Lamp alarm)

|

| 3 |

Measure 10- way inspection , 10 alarm (LED)

|

|

Input

|

1 |

With thermocouple(E、K、S、B、J、T、R、N)

|

| 2 |

With RTD(Ptl00. Cu50. Cul00. BAI. BA2)

|

| 3 |

With DC current( 0-10 mA. 4-20mA)

|

| 4 |

With DC voltage(0-5V. I-5V. 0-20mV. 0-l00mV. 0~500mV)

|

| 5 |

Equipped with remote pressure resistance value and linear resistance value (0-400 Q)

|

|

Control output and regulation mode

|

0 |

Only check the measured value of each channel, no control

|

| 1 |

The upper limit and lower limit alarm values are uniformly set for each patrol inspection channel

|

| 2 |

The upper and lower limit alarm values are set independently for each inspection path

|

| 3 |

The upper and lower limit alarm values of each patrol inspection channel are displayed by the alarm lights or nixie tubes of each channel respectively

|

| 4 |

The upper limit and lower limit alarm values of each channel are set independently, which are displayed by the alarm lights or nixie tubes of each channel respectively

|

| 5 |

The 1-4 channels of the instrument independently use four set values of SP1, SP2, SP3 and SP4, and the 5-16 channels are only for indication

|

| 6 |

Alarm for upper or lower limit of real-time value or average value (SP3 and SP4)

|

| 7 |

SP3's set value monitors the upper and lower limit alarms of all patrol points

|

| 8 |

Four set points (SPI, SP2, SP3 and SP4) can be specified for each channel (at most two set points can be specified for one channel)

|

|

Inspection way

|

1 |

4 -way inspection

|

| 2 |

8 -way inspection

|

| 3 |

12- way inspection

|

| 4 |

16- way inspection

|

|

Dimension

|

H |

Horizontal 160×80

|

portiforium 152×76

|

| V |

Vertical 80×160

|

portiforium 76×152

|

| F |

Square 96×96

|

portiforium 92×92

|

|

Output

|

A |

No output

|

| B |

Output 0~10mA

|

| C |

Output 4—20Ma

|

| D |

Output 0~5V

|

| E |

Output 1~5V

|

| F |

Special signal output

|

|

Output value choice

|

1 |

Immediate value

|

| 2 |

Max. value

|

| 3 |

Min. value

|

| 4 |

Average value

|

|

Timing function

|

S |

No timing function

|

|

With timing function

|

|

Communication port

|

P |

No communication

|

|

With RS485 or RS232 communication port

|

|

Power supply

|

T |

220V.AC

|

|

220V.AC

|

|

|

Note: there are many additional functions available. When ordering, add the serial number and note all. Only one of 4, 5 and 6 can be added with other functions.

|

Technical indicators

1. Measurement accuracy: ± 0.5% FS + 1 word

2. Adjustment control accuracy: bit type: ± 0.5% FS

3. Alarm function: upper limit, lower limit, upper and lower limit, lower return difference, double return difference, etc

4. Input impedance: 0-10mA: 500 Ω, 4-20mA: 250 Ω thermocouple and dcmv

Dcmv: ≥ 10K Ω, automatic compensation accuracy of cold end: ± 0.3 ℃ in the range of 0 ~ 40 ℃

Thermal resistance: full compensation within 3 × ioq of three wire system input

5. Relay contact capacity: ac220v2a

6. Power supply: AC220V ≤ 6W aciov DC24V

7. Working environment requirements: temperature 0-50 ℃, relative humidity: < 85%, no corrosive gas, no vibration

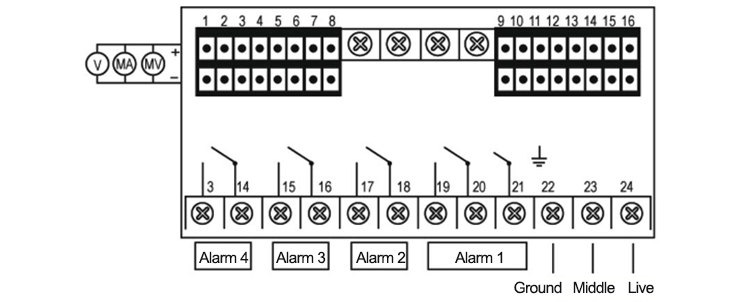

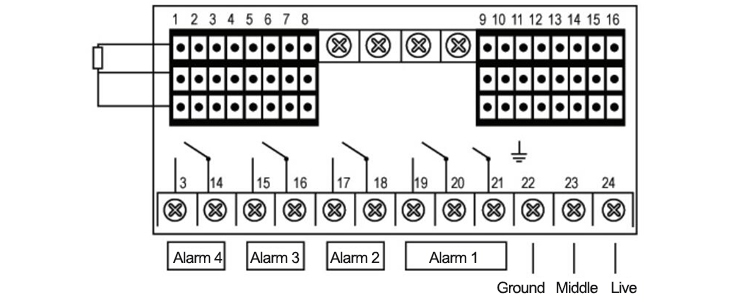

Rear panel and electrical wiring

Horizontal-vertical 16 channels thermocouple V、mV、mA input Wiring diagram

Horizontal-vertical 16 channels RTD input Wiring diagram

Instrument installation

1.1 Before instrument installation, check whether the instrument model, graduation number, measurement range and sensor are consistent.

1.2 instruments are divided into horizontal type and vertical type, including horizontal rectangular type, horizontal square type, vertical rectangular type and vertical square type.

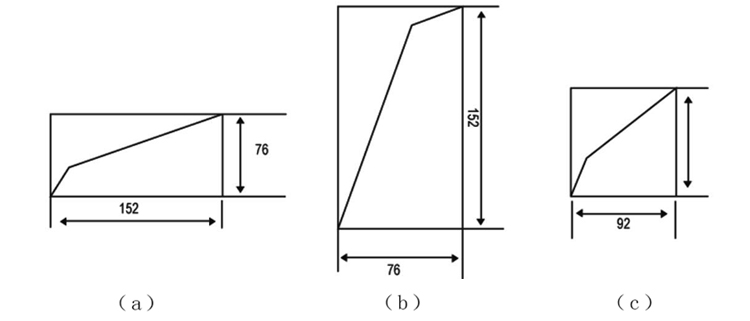

2. Opening size

2.1 horizontal 152 × 76mm (a)

2.2 vertical 76 × 152mm (b)

2.3 square 92 × 92mm (c)

Instrument use and maintenance

1. The instrument shall be placed in a dry and ventilated place without corrosive gas, and the ambient temperature and relative temperature shall meet the technical conditions.

2. The instrument has been aged and calibrated before leaving the factory. If the instrument is damaged during use, the company will repair it free of charge within 12 months from the date of leaving the factory. If the instrument is damaged due to the improper use and storage of the user, the user will repair it at his own cost.