Product overview

Platinum rhodium thermocouples for industrial use are also called precious metal thermocouples. As temperature measuring sensors, they are usually used together with temperature transmitters, regulators and display instruments to form a process control system to directly measure or control the temperature of fluid, steam, gas medium and solid surface in the range of 0-1700 ℃ in various production processes. Platinum rhodium thermocouple is composed of two conductors with different components. When the temperature of two junction points is different, the thermal current will be generated in the circuit. If there is a temperature difference between the working end and the reference end of the thermocouple, the display instrument will indicate the temperature corresponding to the thermoelectric potential generated by the thermocouple. The thermoelectric dynamic heat of Pt Rh thermocouple will increase with the increase of the temperature of the measuring end. Its size is only related to the temperature of the thermocouple material and both ends, and has nothing to do with the length and diameter of the thermoelectric pole. The shapes of various platinum rhodium thermocouples are often very different due to their needs, but their basic structures are generally the same, usually composed of the main components such as thermal electrode, insulating sleeve protective tube and junction box.

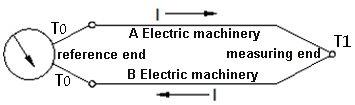

Operational principle

The two ends of two different components of conductor are welded to form a circuit. The direct temperature measuring end is called the measuring end, and the terminal is called the reference end. When there is a temperature difference between the measuring end and the reference end, the thermal current will be generated in the circuit. Connect the display instrument, and the corresponding temperature value of the thermoelectric potential generated by the thermocouple will be indicated on the instrument.

Working principle diagram of thermocouple

Technical parameters

| ★Temperature measurement range and allowable error |

|

TC type

|

Code

|

Graduation

|

Range℃

|

Allowable deviation△t℃

|

|

Platinum and rhodium 30- Platinum and rhodium 6

|

WRR |

B |

600~1700 |

±1.5℃ or±0.25%t |

|

Platinum and rhodium 10- Platinum

|

WRP |

S |

0~1600 |

±1.5℃ or±0.25%t |

Note: "t" is the measured temperature of the temperature sensing element.

|

| |

| ★Stability |

| Stability refers to the change degree of thermoelectric characteristics of thermocouples with the extension of service time. It is an important index reflecting the service life of thermocouples and a destructive test requirement, which can only be done in the product type test. The specific provisions are: after the upper limit temperature of the thermocouple is maintained for 250 hours, the change of thermoelectric potential shall not exceed 50% of the total deviation of measurement accuracy. For example, the stability requirement index of class II precision of type n is: after maintaining at 1200 ℃ for 250 hours, the change of thermoelectric potential before and after the thermocouple test shall be less than 9 ℃ (1200 × 0.75%). |

|

Graduation

|

Allowable deviation

|

Stability

|

| Ⅰ |

Ⅱ |

Ⅲ |

Ⅰ |

Ⅱ |

| S |

±1or±(1+(t-110)×0.3%) |

±1.5 or0.25%t

|

NONE

|

≤1.9 1400℃/250h |

≤3.5 1400℃/250h |

| B |

NONE

|

±0.25%t |

±4or0.5%t |

≤4.25 1700℃/250h |

≤8.5 1700℃/250h |

|

| |

★ Thermal response time

When the temperature changes step by step, the output of thermocouple changes to 5% of the change. The time required is called thermal response time, which is expressed by t0.5.

★ Nominal pressure of thermocouple

Generally, it refers to the static external pressure that the protective tube can bear without breaking under the working temperature. In fact, the allowable working pressure is not only related to the material, diameter and wall thickness of the protection pipe. It is also related to its structure, installation method, insertion depth, flow rate and type of measured medium, etc.

★ Minimum insertion depth of thermocouple

It shall not be less than 8-10 times of the outer diameter of the protective tube (except for special products).

★ Insulation resistance of thermocouple (normal temperature)

The test voltage of insulation resistance at room temperature is DC 500V ± 50V. The atmospheric conditions for measuring insulation resistance at room temperature are 15-35 ℃, 45% relative humidity and 86-106kpa atmospheric pressure.

A. for thermocouples with a length of more than 1 m, the product of their normal temperature insulation resistance value and their length shall not be less than 100m Ω. M Namely: RR. L ≥ 100 Ω. Ml ≥ 1m

Where: R - insulation resistance of thermocouple at room temperature, m Ω

L-length of thermocouple, M

B. for thermocouple with length equal to or less than 1 m, its insulation resistance at room temperature shall not be less than 100m Ω.

★ Upper temperature insulation resistance

The upper temperature insulation resistance of thermocouple shall not be less than that specified in the following table:

|

Upper temperature tm℃

|

Code

|

Graduation

|

| 100≤tm<300 |

t=tm |

10 |

| 300≤tm<500 |

t=tm |

2 |

| 500≤tm<850 |

t=tm |

0.5 |

| 850≤tm<1000 |

t=tm |

0.08 |

| 1000≤tm<1300 |

t=tm |

0.02 |

| tm>1300 |

t=1300 |

0.02 |

|

| |

|

Selection of temperature measuring elements for precious metal thermocouples

|

|

Type

|

Mark

|

Graduation

|

Material

|

Range℃

|

Performance characteristics

|

|

New

|

Old

|

Advantage

|

Disadvantage

|

|

Platinum rhodium thermocouple

|

S |

P |

S |

Platinum rhodium 10- Platinum

|

0~1600 |

It is suitable for oxidizing atmosphere and can be used for a short time in vacuum. High precision and stability, not affected by aging change, oxidation resistance and chemical corrosion resistance, can be used as standard thermocouple

|

It is not suitable for reducing atmosphere (especially H2, metal vapor) and vacuum environment, with high price, low sensitivity and poor linearity of thermoelectric EMF

|

| B |

R |

B |

Platinum rhodium 30- Platinum rhodium 6

|

600~1700 |

Suitable for over 1000 ℃, small thermoelectric potential, no compensation wire, oxidation and chemical resistance

|

It can not be used below 600 ℃, with low sensitivity and poor linearity of thermoelectric potential .

|

|

| |

Structure of thermocouple

It can be seen from the thermometric principle of thermocouples that, in addition to two thermoelectric pole materials, the most basic thermocouple must be made into measuring end and reference end at both ends of the thermoelectric pole according to the requirements, commonly known as "hot end" and "cold end", which is the so-called "two ends".

According to the different uses of thermocouples, the hot end has four types: insulation type, multi branch insulation type, shell type and exposed type, and the cold end has two types: sealed and unsealed.

The thermocouple is generally composed of five parts. Two thermoelectric poles (or even wires) are the core part of the thermocouple (the first part of the temperature measuring element), and the other parts are all around it. In order to ensure that the thermal potential in the circuit is not lost to accurately transmit the measured temperature signal, insulating materials must be used to make the other parts of the two thermoelectric poles except the two ends and between them and the outside Reliable insulation (Part II insulation materials); in order to protect the insulation materials and even wires and extend the service life of thermocouples, protective sleeves (Part III protective tubes) are generally designed; in order to install wiring and use conveniently, and adapt to various use occasions, Part IV wiring device and Part V installation and fixing device are generally designed. These are the so-called "five parts"

According to different purposes, the most basic thermocouple (thermocouple core) that can measure temperature has no protective tube and fixed device , The assembled thermocouple is mainly composed of junction box, protective tube, insulating sleeve, terminal block, thermoelectric pole, and various installation and fixing devices.

Specifications

| |

|

Model

|

Graduation

|

Range℃

|

Specification

|

Installation type |

|

Diameter mm

|

Protection tube material

|

Thermal response time

|

| WRP-130 |

S |

0-1300 |

16 |

Corundum tube

|

<150 |

Directly insertion |

| WRP2-130 |

| WRR-130 |

B |

600-1600 |

| WRR2-130 |

| WRP-230 |

S |

0-1300 |

Fixed thread |

| WRP2-230 |

| WRR-230 |

B |

600-1600 |

|

WRR2-230

|

| WRP-330 |

S |

0-1300 |

Movable flange |

| WRP2-330 |

| WRR-330 |

B |

600-1600 |

| WRR2-330 |

| WRP-430 |

S |

0-1300 |

Fixed flange |

| WRP2-430 |

| WRR-430 |

B |

600-1600 |

| WRR2-430 |

|

|